Elementary Knowledge of Screws

Machine screws are extensively used for securing parts. The number of different types and sizes of machine screws, nuts & bolts prohibit the possibility of introducing them all here so the following information addressed the elementary information only.

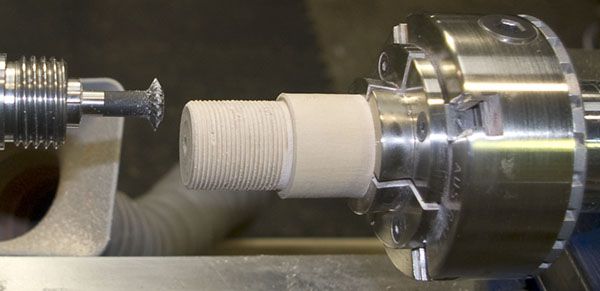

Jan 15, 2003 Fig. 6—This custom thread turning tool is used to machine two separate threads simultaneously on a six-spindle lathe. The threads used to be machined one at a time. The inserts used here were actually intended for a thread milling tool, but they are applied here as turning inserts. ■ If you do a lot of threading on a manual lathe, invest in a tool that accepts inserts. The inserts are precisely ground and easily changed. One insert cuts dozens of thread pitches. ■ I learned how to thread on the lathe using the compound infeed method.

Nov 23, 2015 5) Wind the crosslide back in to zero and continue feeding the tool in using the compound. When the compound gets to zero you are at depth. One simple calculation for depth and you don't have to remember your last reading on the dial. Unified Depth of thread. External =.61343/TPI Internal =.54127/TPI (Minimum). Using a die handle is a common method of external thread cutting on the lathe. The workpiece is clamped in the lathe chuck, and the threading die is held and rotated using a die handle. In general, round-shaped dies are for cutting threads onto a workpiece and hex-shaped dies are for chasing (cleaning up / repairing) existing threads. My 2000 4X4 Frontier has just over 200,000 miles on it. I have pretty much kept up with oil changes at regular intervals (mostly conventional oil), maybe a couple times going 7,500 miles or so between oil changes, maybe once going even longer than this. A manager at an auto parts store talked me.

Types of Threads

Almost of the thread have triangle shaped threads. On the other hand, square shaped and trapezoid shaped thereads are used moving machinery which need high accuracy, such as a lathe.

In respect to thread standards, there are a metric thread (M), a parallel thread for piping (PF), a taper thread for piping (PT), and an unified thread (UNC, UNF). The following information is related metric threads, because they are the most widely used in Japan and many countries around the world.

Terms used for Threads

Figure 1 shown an image of a thread. One of the most important terms used is that of the outer diameter. In the case of a metric thread, the bolt is named in accordance with its outer diameter e.g a bolt with a 5 mm outer diameter is known as an M5 bolt.

The 'Pitch' of the tread is another important feature of a thread. The pitch is defined as the interval (distance) between adjoining threads. e.g. Nuts & bolts must have the same pitch as well as diameter if they are going to be used together.

The principles of cutting threads in nuts and bolts is that the bolt (male thread) is usually cut from a rod of material which has the same diameter has the intended finished bolt. The nut is made from a larger stock witch has a hole drilled through it that is slightly larger than that of the rod diameter. A thread of the same pitch is then cut which results in two mating threads. The same principles apply for cutting holes in places and other work pieces. (such an in the cylinder discussed earlier.)

Screw and Clearance Hole

Screws are typically used for securing mating parts. When two pieces are joined together using screws, one piece is made with threads, and another piece is made with clearance holes, which have bigger diameters than that of the screws. If the diameter of the clearance hole is too small, the piece cannot be assembled as the screw will not fit through the hole. Also, if the diameter of the clearance hole is too big, , the piece will be loose as the hole will provide a sloppy fit. Therefore, we must provide make suitable diameter clearace holes. As a 'rule of thumb', the diameter of the clearance hole has more 10 % than the diameter of the screw. For examples, the clearance hole for a M3 screw has 3.2 mm or 3.5 mm diameter. the clearance hole for a M4 screw has 4.2 mm or 4.5 of diameter. And we would make a hole with 5.5 mm of diameter for a M5 screw.

Thread Making Process

When we make the male thread, generally we use a die tool. When we make the female thread, we use a tap tool. If we do not have the suitable tools, we can also make the thread using a lathe as described in Chapter 3.

Threading Using A Lathe The Mechanic Tools

CautionWhen we make the threads using the tap or the die, care should be taken in respect for the following.

Internal Threading Lathe

(1) Start the thread with a perpendicular positioning of the tap or the die.

(2) Turn the tap or die in quarter turns and 'back off' quarter turns to remove melat chips so that they don't clog the tool.

(3) Always use a cutting oil.

Tread Cutting using a Hand Tap

Figure 5 shows taps which are used to make female threads. They are usually used with a tap handle as shown in Figure 6. In respect to the tread cutting process, we first, we make a hole with suitable diameter and suitable depth (see Table 1). Next, we start to turn the tap in a clockwise direction.

There are typically three types of taps used as seen in figure 5. Of the three tap types there is a tapered tap to facilitate the initial thread cutting, an intermediate type that is used to progress the thread after it has been started and then finally, a 'Bottoming' thread which is used to obtain the full thread depth when cutting a thread that does not go the whole of the way trough the piece.

Recommended Tap Hole Size

Table 1 lists diameters of hole sizes for metric female threads and piping threads (PT, PF). Please note that the diameter of the hole equals the approximate difference of the diameter of the thread and the thread pitch. It may be necessary the allow a grater hole clearance if for example we were making a thread in hard stainless steel.

Lathe Threading Chart

Cutting using a Hand Die

Figure 8 shows a die and a die handle which are used to make male threads. The procedure of the threading is the same of the taps. But it is more difficult to start the thread cutting process than with tapping as dies do not have an equivalent to a tapered starting tap with perpendicular than the tapping.

The thread cutting process using a die usually typically results in a smaller diameter of the original piece so care needs to be taken in selecting the correct size stock. If the stock is too small, this will result in a shallow thread depth resulting in an unsatisfactory thread. The die also created a bevel on the thread which is necessary for a close fit.

If you have a lathe, the job of cutting a thread can be easier as it is possible to use the 'STOPPED' lathe to assist in starting the thread as shown in figure 9. The die is pushed by the drill chuck aligned perpendicularly to the piece and after. After enough thread is cut, the drill chuck is removed and the die handle is then turned by hand.

More on Threads

How does the screw make perpendicularly?

If the thread needs to be held perpendicular to the piece, then it is important that the thread incorporate a shoulder to act as a 'load bearing surface' as depicted in figure 10.The threaded section does not have the mechanical properties necessary to remain perpendicular without such a shoulder.

Threading Using A Lathethe Mechanical

Threading Using A Lathe The Mechanic Machine